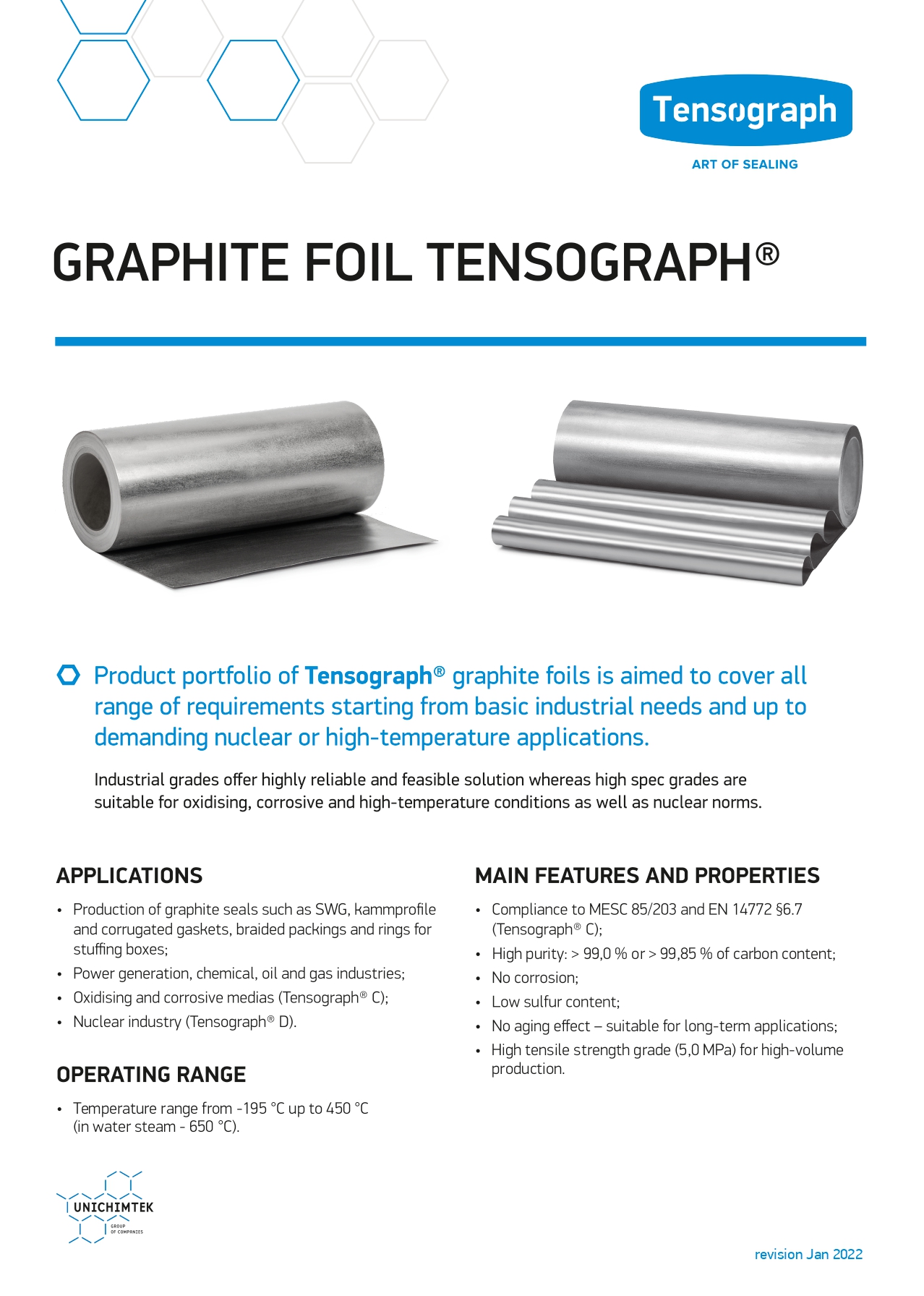

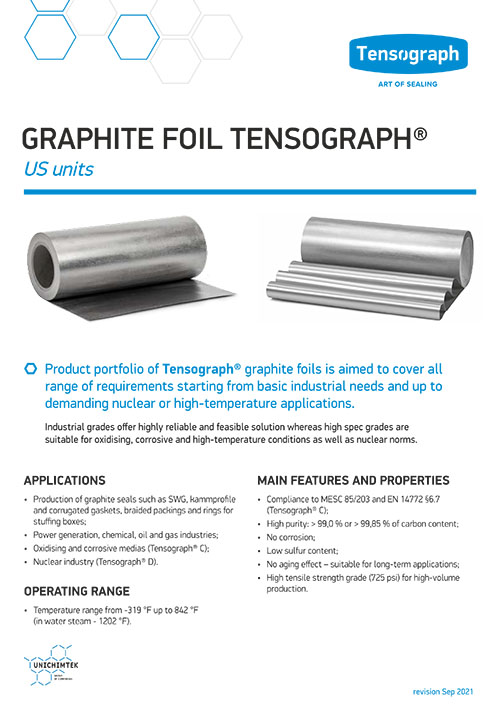

Graphite slit tapes TENSOGRAPH®

Slit tapes TENSOGRAPH® are manufactured with the use of a whole range of TENSOGRAPH® graphite foil with further cut to any required width upwards 4 mm / 1/8 " with high precision which makes it an excellent filler for production of quality spiral wound gaskets and graphite die-molded rings.

Due to special patented technology TENSOGRAPH® tapes could be produced with high strength which solves the problem of breaking-up of filler for SWG's and graphite rings production.

Huge length of winding (up to 100m / 330’) makes possible longer continuous production and manufacturing of large diameter SWG’s.

APPLICATIONS:

Filler material for spiral wound gaskets and die-molded rings.

MAIN FEATURES AND PROPERTIES:

-

Huge length of winding (up to 100m / 330’);

-

Consistently accurate width and high strength;

-

Resistance to high temperatures;

-

Impermeability to gases and fluids;

-

Zero sulphur and halogen content;

-

Anti-sticking properties in accordance with ASTM F607;

-

Fire-safety approved (API Specification 6FB – Tensograph® C);

-

Absence of binders.

FORMS OF SUPPLY

Thickness …………………….. 0.38, 0.5, 0.76 mm / .015, .020, .030”

Width ……………………………4.0 – 130 mm / 1/8 - 5”

Length of winding ……….. 30, 50, 60, 90, 100 m / 100, 165, 200, 330’

Density …………………………. 1.0, 0.7, 1.12 g/cc / 62, 44, 70 lb/ft3

AVAILABLE OPTIONS OF GRAPHITE FOIL TENSOGRAPH®

|

Parameter |

Grade B Industrial |

Grade G High-purity |

Grade D Nuclear |

Grade C Anti-oxidation and аnti-corrosion |

Grade T High-purity and oxidation resistant |

Grade 1T Ultra-low losses |

|

Carbon, % |

> 98,0 |

> 99,0 |

> 99,85 |

> 98,0 (99,0*) |

> 99,0 |

> 98,0 |

|

Ash, % |

< 2,0 |

< 1,0 |

< 0,15 |

< 2,0 |

< 1,0 |

< 2,0 |

|

Sulfur, ppm |

< 200 |

< 100 |

< 50 |

< 100 |

< 100 |

< 100 |

|

Chlorine**, ppm |

< 40 |

< 40 |

< 20 |

< 40 |

< 20 |

< 20 |

|

Fluorine**, ppm |

< 20 |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

Total halogens (Cl+F+Br)** , ppm |

< 200 |

< 100 |

< 50 |

< 200 |

< 100 |

< 100 |

|

Tensile strength, MPa |

> 4,5 (> 700 psi) |

> 4,5 (> 700 psi) |

> 4,0 (> 700 psi) |

> 5,0 (> 725 psi) |

> 5,0 (> 725 psi) |

> 5,0 (> 725 psi) |

|

Compressibility, % |

> 40 |

> 40 |

> 40 |

> 40 |

> 40 |

> 40 |

|

Recoverability, % |

> 10 |

> 10 |

> 8 |

> 10 |

> 10 |

> 10 |

|

Oxidation and corrosion inhibitor |

- |

- |

- |

yes |

yes |

yes |

|

Weight loss (670 °C / 1238 °F), %/h |

< 12 |

< 12 |

- |

< 4 |

< 3 |

< 1 |

|

Compliance to special requirements |

DVGW DIN 3535-6 |

BAM; ASTM F2168 class 2 (B) |

PMUC norms; GS RC PVE 011; BAM; ASTM F2168 class 2 (B) |

MESC 85/203; EN 14772 §6.7; ASTM F2168 class 2 (A); DIN-28091-4 |

MESC 85/203; EN 14772 §6.7; ASTM F2168 class 2 (A); DIN-28091-4 |

MESC 85/203; EN 14772 §6.7; ASTM F2168 class 2 (A); DIN-28091-4 |

* initial carbon content (before inhibitors added)

**leachable

Download materials